Thermal stability of tungsten carbide road milling tools: where is the breakthrough point in the future

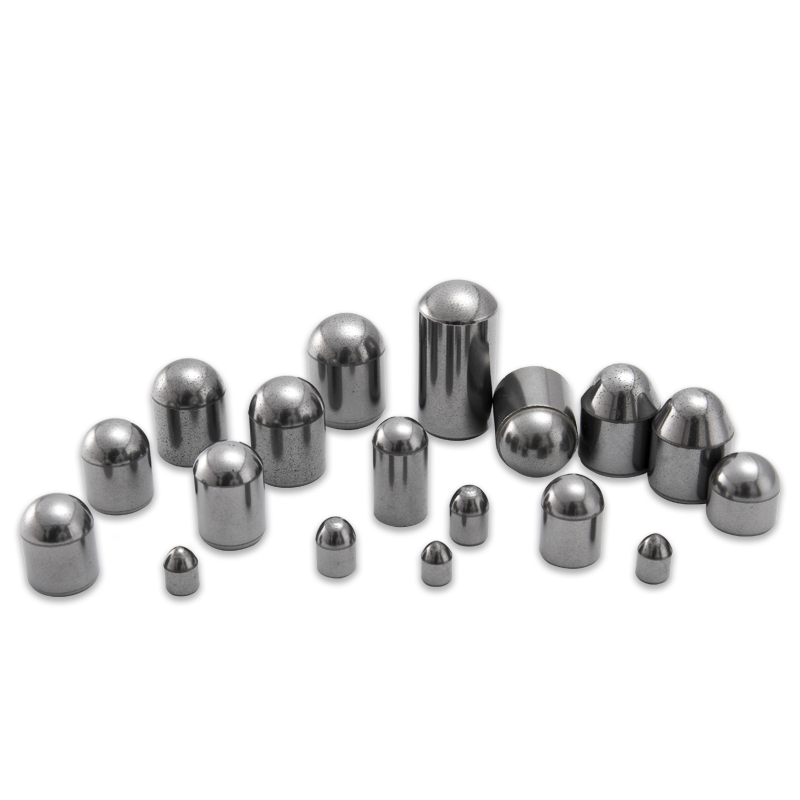

Industry News-Tungsten carbide road milling tools are indispensable tools in road construction and maintenance, tasked with the crucial roles of leveling and cutting road surfaces. In road milling operations, the performance of these tools directly impacts operational efficiency and work quality. Among these factors, thermal stability stands out as a critical determinant of the tools' lifespan and performance under high-temperature conditions.

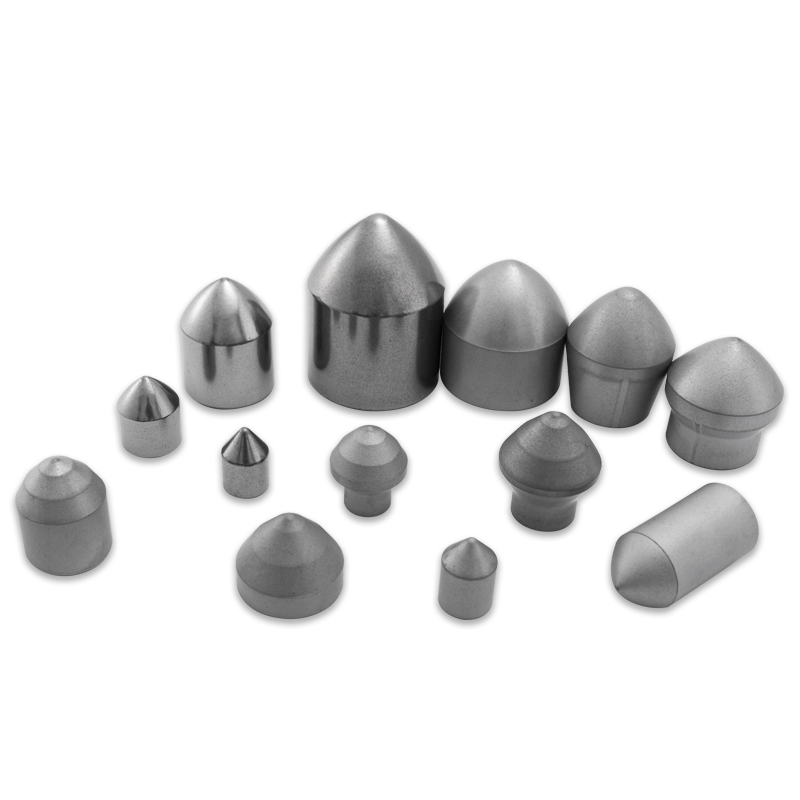

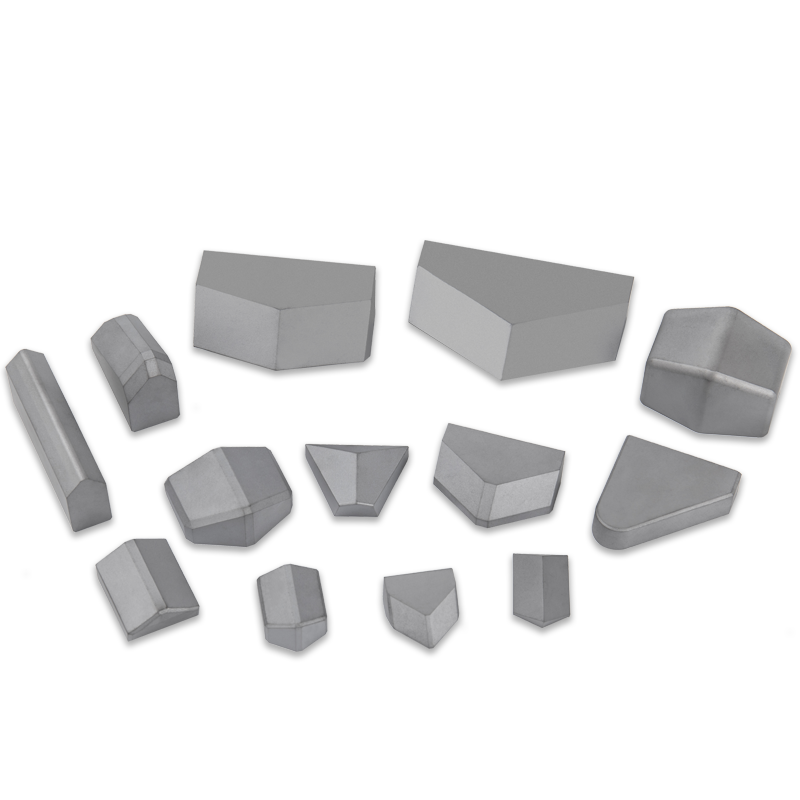

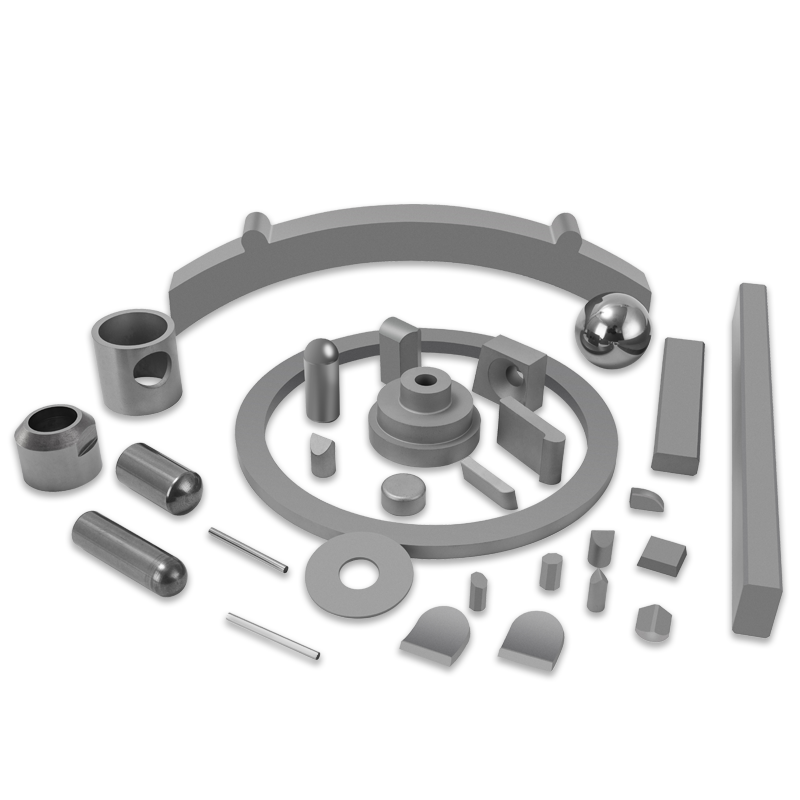

Hard metal alloys, typically composed of tungsten carbide (WC) particles and a cobalt (Co) matrix, constitute a type of metal matrix composite. The tungsten carbide particles provide exceptionally high hardness and wear resistance, while cobalt as the matrix enhances overall toughness and strength. This combination enables hard metal alloys to perform exceptionally well under high-intensity cutting conditions, particularly suitable for industrial sectors demanding high tool wear resistance.

During road milling operations, milling tools operate under conditions of high-speed rotation and high temperatures. These conditions subject the tools to elevated temperatures and intense impact forces generated from road surface friction. Hence, thermal stability of milling tools becomes critically important, directly influencing milling efficiency, costs, as well as operator safety and equipment reliability.

The thermal stability of hard metal alloys is primarily influenced by their composition and microstructure. Firstly, the high melting point of tungsten carbide (approximately 2870°C) and its high hardness (Mohs hardness of about 9 to 9.5) enable hard metal alloys to maintain good structural stability and cutting performance at high temperatures. Secondly, cobalt, acting as a binder, not only helps in anchoring tungsten carbide particles but also provides a degree of toughness and resistance to thermal expansion at high temperatures, thereby reducing tool deformation and breakage during operation.

To further enhance the thermal stability of tungsten carbide road milling tools, specific heat treatment processes and process controls are commonly employed. For instance, precise sintering processes can effectively control the bonding strength between tungsten carbide particles and the cobalt matrix, thereby enhancing overall thermal stability and impact resistance. Additionally, optimizing the geometric shape and cutting edge design of milling tools can reduce stress concentration and wear under high-temperature conditions, thereby extending the tool's service life.

In addition to stability under high-temperature conditions, tungsten carbide road milling tools also require good environmental adaptability and corrosion resistance. This ensures stable cutting performance under different weather and road conditions, such as wet, dusty, or stony environments, minimizing susceptibility to external environmental factors that could lead to premature tool failure.

The thermal stability of tungsten carbide road milling tools is a critical factor influencing their performance. Through optimized material formulations, heat treatment processes, and tool design, it is possible to effectively enhance the tool's lifespan and cutting efficiency under high-temperature conditions, meeting the requirements for cutting quality and equipment reliability in road construction and maintenance work. Looking forward, with continuous advancements in materials science and process technology, the performance of tungsten carbide road milling tools in terms of thermal stability is expected to further improve, delivering greater benefits and safety assurances to the field of road engineering.

English

English русский

русский