What is tungsten carbide and why is it suitable for stamping dies

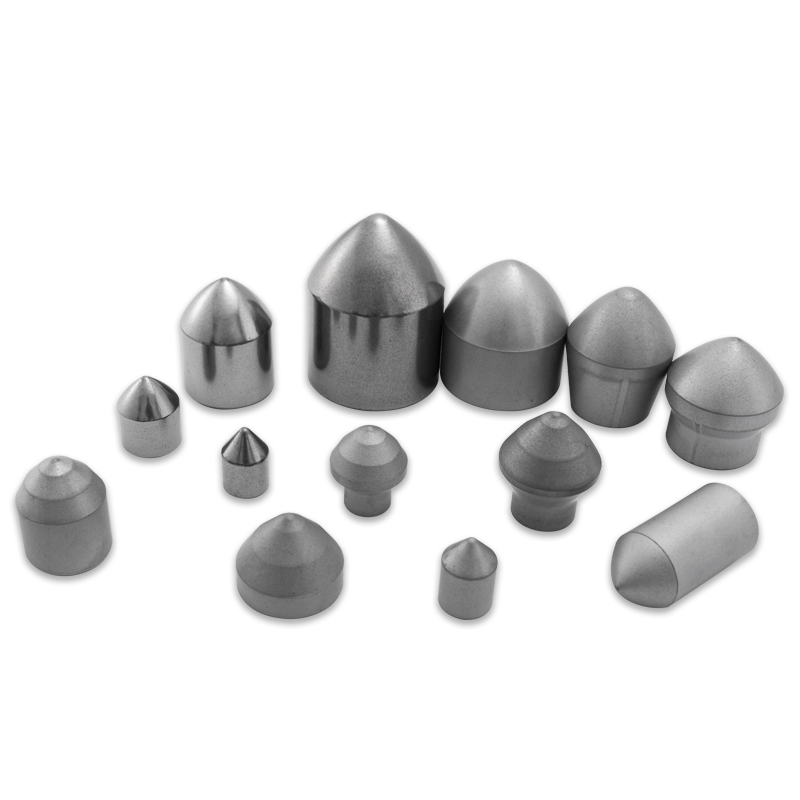

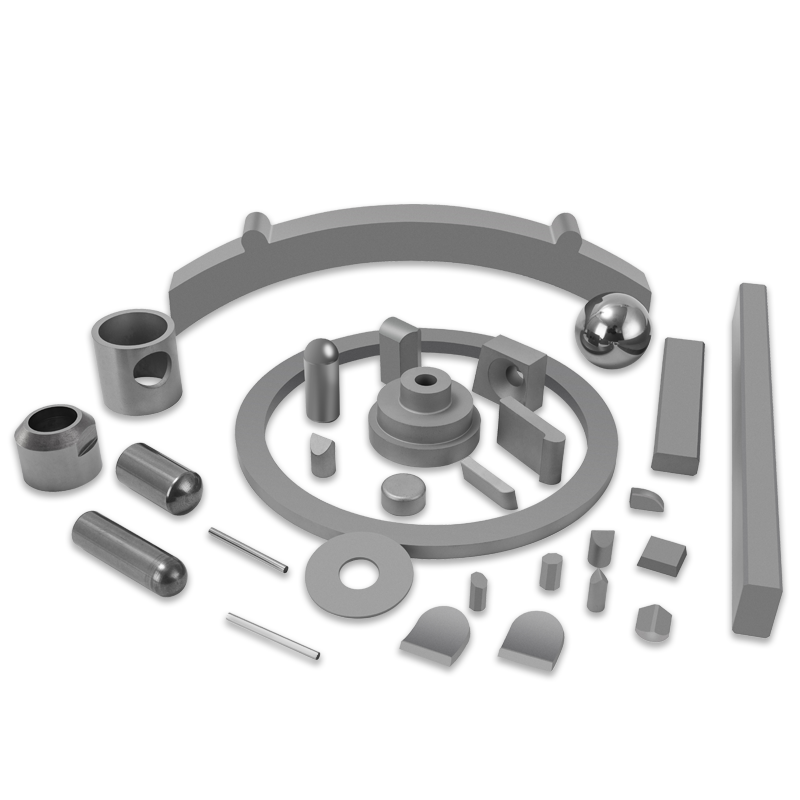

Industry News-Tungsten carbide is a composite material that is composed of equal amounts of tungsten (W) and carbon (C) atoms combined. This synthesis produces a very hard and dense material known for its excellent mechanical properties. Typically, tungsten carbide is produced through powder metallurgy technology, where tungsten powder and carbon black are mixed, pressed into the desired shape, and then sintered at high temperatures to achieve the final hardness and density.

Why tungsten carbide excels in stamping dies:

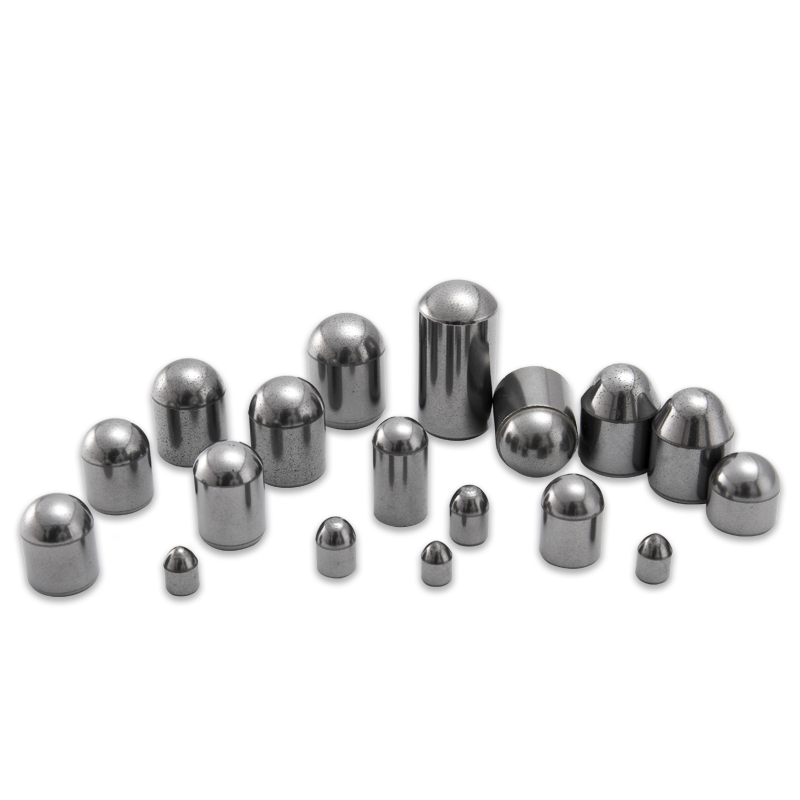

Hardness and wear resistance:

Tungsten carbide is known for its extremely high hardness - about 80 to 90 Rockwell hardness (HRA or HRB). This property far exceeds that of most tool steels. This hardness is critical for stamping dies, as repeated contact with metal will quickly wear away softer materials. The hardness of tungsten carbide ensures extended tool life and reduced replacement downtime, making it highly cost-effective in the long run.

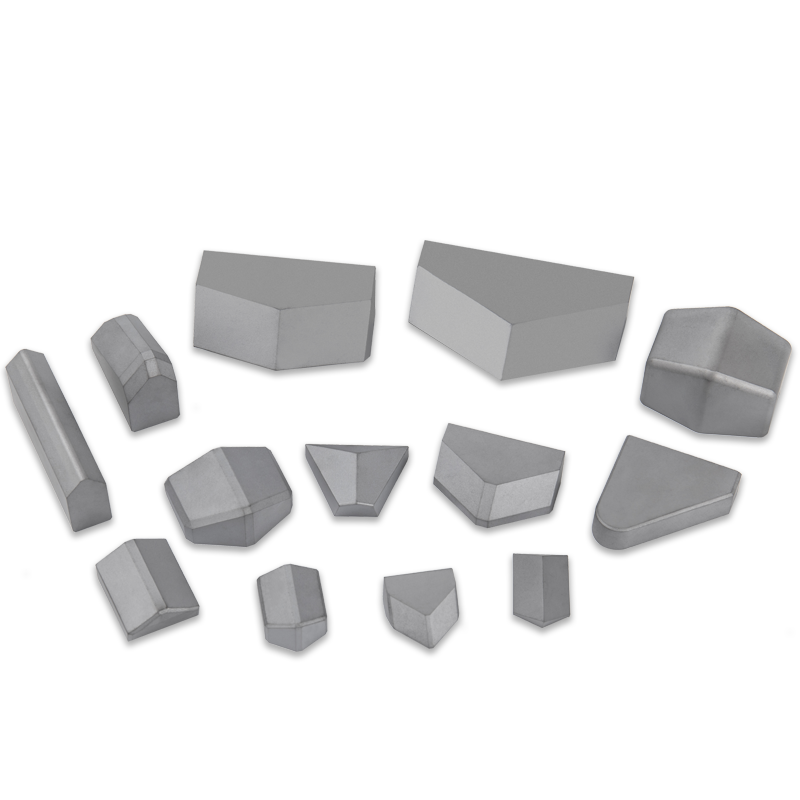

Excellent wear resistance:

The wear resistance of tungsten carbide is unmatched in industrial applications. Its resistance to wear, even under high stress conditions, ensures that stamping dies maintain their precise dimensions and surface integrity after extended use. This reliability is critical in industries such as automotive, aerospace, and electronics where part quality and dimensional accuracy cannot be compromised.

High Compressive Strength:

Tungsten Carbide Stamping Die operations often involve significant forces and pressures. Tungsten carbide’s high compressive strength enables it to withstand these forces without deforming or failing. This property ensures that dies can withstand the rigors of the stamping process, including deep drawing, punching, and blanking, without compromising performance.

Chemical Inertness and Corrosion Resistance:

Unlike many metals, tungsten carbide is chemically inert and highly resistant to corrosion by acids, bases, and other harsh chemicals. This corrosion resistance makes it suitable for use in a variety of industrial environments with frequent exposure to chemical agents. It ensures long life and reliability in applications where tool durability and stability are critical.

Temperature Stability:

Tungsten carbide exhibits exceptional thermal stability, maintaining its hardness and mechanical properties even at elevated temperatures. This property is particularly advantageous in stamping processes involving hot materials or where high operating temperatures are present. It enables tungsten carbide dies to operate efficiently without significantly reducing performance or dimensional accuracy.

Dimensional Accuracy and Stability:

Precision engineering requires tools that can maintain consistent dimensional accuracy over time. The inherent dimensional stability of tungsten carbide ensures that stampings repeatedly meet precise specifications, helping to improve overall manufacturing efficiency and product quality.

English

English русский

русский